Environmental protection

The Environmental Policy of the Company’s power grid complex sets out the goals to decrease the negative impact on the environment and support environmental safety at power grid facilities, upgrade equipment and employ innovative and eco-friendly technologies during reconstruction, retrofitting, and electric grid construction, as well as the rational use of natural resources

In the reporting year, all of the schedule environmental policy actions were implemented, among them:

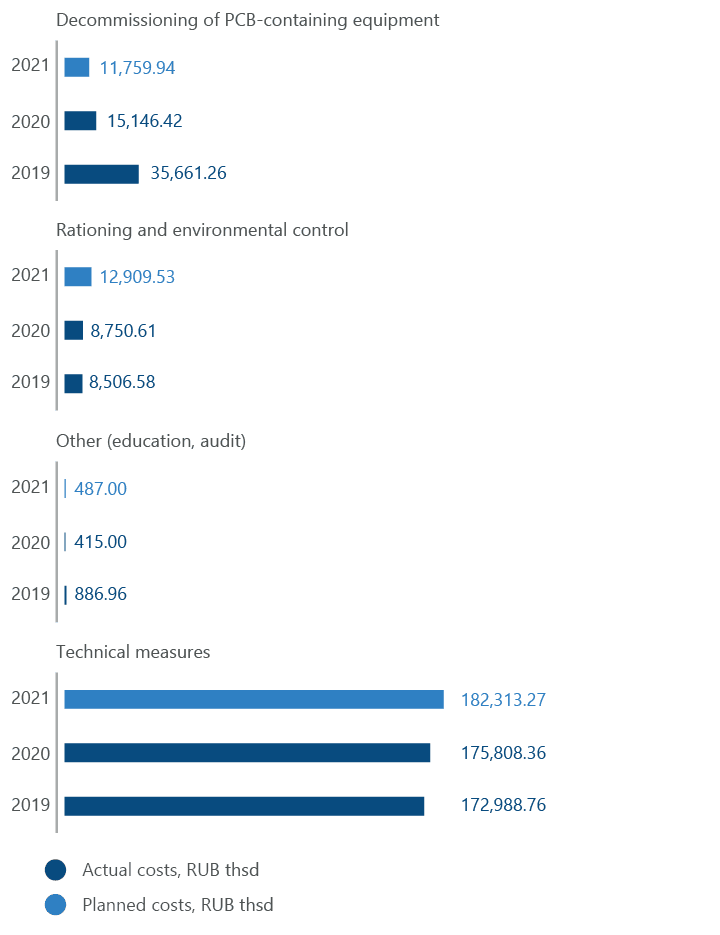

- meeting the requirements of the Stockholm Convention on Persistent Organic Pollutants: 631 units of equipment containing polychlorinated biphenyls (PCBs) were decommissioned and replaced with environmentally friendly ones. The environmental policy of the power grid complex has set the task of 100% decommissioning of equipment containing PCBs, with its subsequent transfer for destruction by 2025. The phased decommissioning of such equipment follows up on the decommissioning plan for PCB-containing equipment for 2018–2023 approved by the decision of the Board of Directors of PJSC Kubanenergo (Minutes No. 296/2018 dated January 23, 2018);

- respecting requirements of the Russian Environmental Laws by the Company:

- industrial environmental monitoring at pollutant sources, sanitary protection zone boundaries, pollutant water discharge points to check the compliance with the set standards for acceptable environmental impact;

- development and approval of sanitary protection zone projects by controlling bodies for 15 power facilities of the Power Grids of Adygea, Armavir, Krasnodar, Labinsk, Leningrad, Slavyansk, Sochi, Timashevsky, Tikhoretsky, Ust-Labinsk, the South West and the Company’s executive office to designate special areas acting as buffers and providing the protection for the residents during the operation of the unit;

- taking technical actions to reduce the adverse impact on the environment:

- replacement of 80 oil circuit breakers with the vacuum or SF6 circuit breakers to reduce the risk of oil spillage and soil, groundwater, and air contamination;

- replacement of 180 oil-filled bushings with solid-insulation bushings;

- repair (reconstruction) of emergency oil discharge systems and transformer oil receivers at 19 substations to prevent potential environmental contamination;

- construction/reconstruction of a 761.05-km long OPL using self-supporting insulated wires, including to the biodiversity preservation purposes;

- installation of a total of 4,978 bird guards to preserve the biodiversity and prevent animal kills in production processes;

- recycling/recovery of up to 20 tons of transformer oil (~10% of the oil purchased per year) to reduce the amount of natural resources consumed;

- continuous updating of voluntary environmental responsibility mechanisms.

The environmental management system of the Company was introduced, assessed and certified as compliant with the requirements of ISO 14001 international standards for the Systems of Environmental Management since March 2009, which allows the Company to efficiently control the environmental risks, prevent and mitigate the adverse environmental impact and improve its image.

According to the results of the recertification audit of 2020 conducted by SGS Vostok Limited JSC, the Company successfully confirmed its compliance with the new revision of ISO 14001:2015 standard for the systems of environmental management.

Rosseti Kuban adversely affects the natural environment components by transferring the most efficient type of energy to consumers – electric energy.

Key sources of the Company’s environmental impact include:

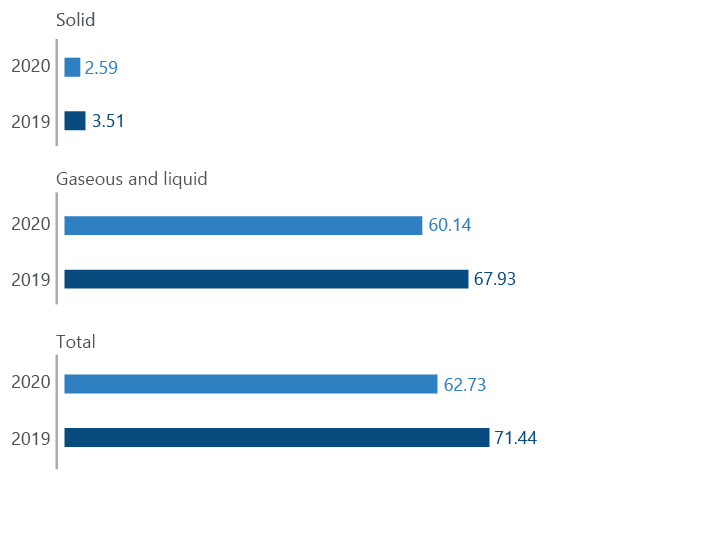

- operation of vehicles, machines (cutting, drilling, woodworking, turning and sharpening), the performance of welding and painting works, chemical analysis of transformer oils, transformer oil storage. The gross atmospheric emissions in 2020 decreased by

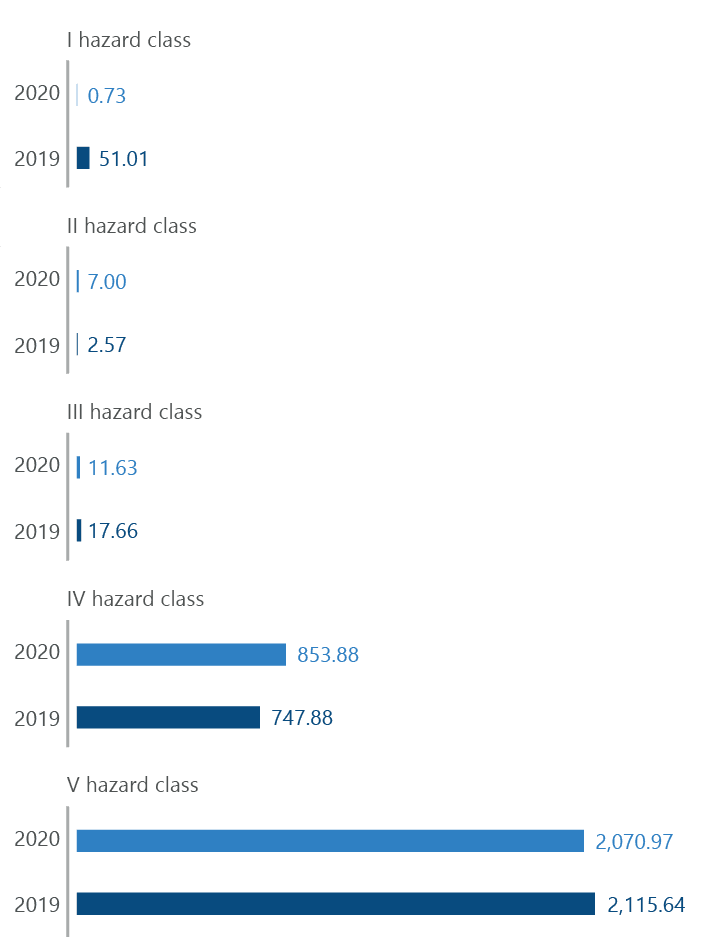

6.4% on a year-on-year basis; - accumulation of wastes generated from the Company’s operational and business activities and their further handling (handing-over to specialized companies for further processing, disposal, neutralization, and storage).

Taking into consideration that the priority area of the current state policy for waste management is their disposal providing for the maximum use of all waste components, the Company in 2020 handed over 16% more of wastes to specialized disposal organizations than in 2019.