Occupational Safety and Industrial safety

Occupational Safety

The key principle of the occupational safety activities of Rosseti Kuban is the recognition of and supporting the priority of employees’ lives and health as compared to the results of the Company industrial activities.

The occupational safety initiatives of the Company is aligned with the statutory requirements of the Russian Federation, regional laws, industry sector codes and rules, executive documents. During 2020, the occupational safety system was subject to systematic improvement at all divisions of the Company with a view to prevent job-related injuries and promote better working conditions as required by the master documents on occupational safety.

Maintaining safe working conditions and labor safety at Rosseti Kuban and their compliance with the requirements set is the responsibility of the Company management. The Company fully complies with the requirements of the Russian laws regarding the employees occupational safety obligations of the employer.

With a focus on better occupational safety management and fewer occupational injuries, preserving the life, health and working capability of employees, their better compliance with the requirements of legislative and regulatory acts on occupational safety, supporting occupational safety and preventing occupational diseases, the Company declared the 2020 year to be the zero accident year, refer to Order No. 2 dated January 9, 2020 On the Occupational Safety Performance in 2019 and Tasks for 2020.

To establish a unified labor management system in the Company and to ensure safe and normal working conditions for employees at all stages of production, to monitor the compliance with occupational safety requirements at all levels of corporate management, the Company adopted STO 00104604-ISM 007–2018 Regulations on the Occupational Health and Safety Management System, which met the requirements of GOST 12.0.230–2007, interstate standards for occupational health and safety management systems, as well as the labor legislation of the Russian Federation. During the year, the Company did the follow-up revision of the management system and implemented the requirements of the international standard ISO 45001.

The main occupational safety goals of Rosseti Kuban are as follows:

- ensuring safe working conditions for employees;

- prevention and maximum reduction of occupational risks to the health of employees and employees contracted to work at the Company’s power grid facilities.

The Company’s management (the management of the Company’s branches) annually analyses and evaluates the achievement of the occupational safety goals. Following the functional analysis of the occupational health and safety management system in 2020, the Company considers the effectiveness of the total corporate efforts invested to be satisfactory.

In conformity with the labor laws of the Russian Federation, in order to create and support a unified occupational health and safety management system in Rosseti’s Group of Companies, as well as to improve and upgrade the efficiency of the industrial safety system, the Company adopted the corporate standards approved by the order of Rosseti as documented procedures for the occupational health and safety management system.

According to the analysis of the existing executive documents of Rosseti, regulating the occupational safety processes and activities within Rosseti Group, the Company approved and started implementing comprehensive programs to reduce injury risks for Kubanenergo’s personnel and third parties at the power grid facilities of the Company between 2018 and 2022 in order to reduce the injury risks at the power grid facilities and implement the long-term development program of Rosseti. The goal and objective of comprehensive programs is to prevent industrial injuries and the death of third parties from electric shock. Programme actions scheduled for 2020 were performed to the full extent.

In the reporting year, the Company performed occupational safety actions developed following the requirements of order No. 181n of the Ministry of Healthcare and Social Development of Russia dated March 1, 2012 On Approval of Standard List of Annual Employer Events For Improvement of Working Conditions and Occupational Safety and Professional Risks Mitigation. The Company controls the employees’ compliance with the workplace safety statutory requirements for arranging and performing works at power units. A behavior audit is conducted at the Company (safe work arrangement observations). The audit’s results were translated into measures aimed towards the elimination and prevention of violations, including psychocorrective classes.

To coordinate the health care and occupational safety activities of the Company’s branches, monthly selector meetings were held in the form of video conferences that involved first deputy directors – chief engineers and department heads of the Company branches. Occupational safety days are conducted on a monthly basis, which helps involve more Company’s employees in the process of self-control and mutual control and increase the level of employee knowledge and experience in occupational safety and safety regulations.

Some training sessions were held at the Company branches to explain the functioning of the occupational safety system and to determine potential threats and risks for employees’ health and safety in a timely manner in a form of business games involving the specialists for psychophysiological reliability of professional activities.

In 2020, the internal technical control system required comprehensive checks on compliance with the requirements of regulatory and technical documents, regulatory legal acts relating to the operation of electrical installations, the requirements for the safe operation of hazardous production facilities, and the Company’s organizational and administrative documents aimed at preventing industrial accidents and injuries of third parties in the Company’s branches – Power Grids of Adygea, Labinsk, Leningrad and Ust-Labinsk. In order to prevent and prevent the spread of COVID-19 coronavirus infection in the Company’s divisions, comprehensive inspections were carried out remotely in accordance with standard inspection programs posted on the network resource of Rosseti Kuban.

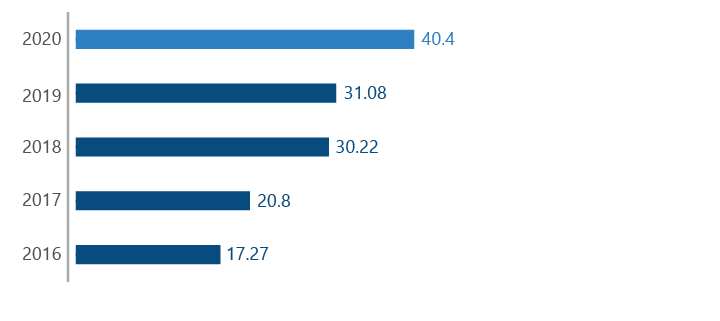

Following the Labor Code of the Russian Federation, the actions aimed at improving the working conditions and occupational safety at the Company are funded to at least 0.2% of the manufacturing costs for products (works, services); in fact, these activities were financed in the amount of

During 2020, there were three accidents involving the Company’s employees.

Occupational diseases of the Company’s personnel were not diagnosed in 2020.

To promote employees’ health and wellbeing, the Company purchased necessary protection and safety equipment for the performance of works in 2020. The annual purchase order for special clothing and shoes was completed to the full extent.

Industrial safety

The operational supervision for industrial safety is aligned with the Company’s order No. 405 dated July 13, 2020 On the Appointment of Persons Responsible for Operational Supervision for Industrial Safety Requirement Implementation at Hazardous Facilities and with the Regulation of Operational Supervision for Industrial Safety Requirement Implementation at Hazardous Facilities of the Company dated June 9, 2020 based on:

- Federal Law No. 116-FZ dated July 21, 1997 On Industrial Safety of Hazardous Production Facilities;

- Order No. 461 of the Federal Service for Environmental, Technological and Nuclear Supervision dated November 26, 2020 On Approval of Federal Standards and Rules for Industrial Safety of Hazardous Production Facilities, Safety Rules for Hazardous Production Facilities with Hoisting Equipment;

- Decree of the Government of the Russian Federation No. 2168 dated December 18, 2020 On the Organization and Implementation of Production Control over Compliance with Industrial Safety Requirements.

Rosseti Kuban has three hazardous production facilities registered at the Federal Service for Environmental, Technological and Nuclear Supervision (certificate No. А30–00777 dated October 13, 2020). In 2020, the hazardous production facilities were operated following the requirements set out in technical reference documents.

Only the employees who went through proper training, pre-examination training and knowledge check for industrial safety rules were permitted to perform works related to the operation of the hazardous production facilities of the Company and the technical equipment installed there. Training, pre-examination training, initial and recurring knowledge assessment for engineering staff are done at specialized organizations holding relevant permits.